|

AL404001 |

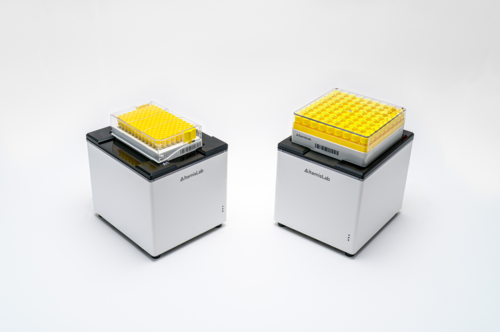

AlteCap™ Solo - Altemis Tube |

|

AL404100 |

AlteCap™ Solo - Internal thread Matrix (96 SBS format) |

|

AL404102 |

AlteCap™ Solo - Internal thread Micronic screw caps (96 SBS format) |

|

AL404104 |

AlteCap™ Solo - External thread LVL screw caps (96 SBS rack format) |

|

AL404107 |

AlteCap™ Solo - Internal thread Greiner screw caps (96 SBS format) |

|

AL404108 |

AlteCap™ Solo - External thread fluidX screw caps (96 SBS format) |

|

AL404109 |

AlteCap™ Solo - Internal thread Hamilton screw caps (96 SBS format) |

|

AL404114 |

AlteCap™ Solo - External thread Eppendorf screw caps (96 SBS format) |

|

AL404116 |

AlteCap™ Solo - External thread NEST screw caps (48 SBS rack format) |

|

AL404117 |

AlteCap™ Solo - Sarstedt tubes (custom rack available) |

|

AL404120 |

AlteCap™ Solo - Azenta Acoustic Sample Tube |