Silvia Pisani, Rossella Dorati, Franca Scocozza, et al

University of Pavia

Challenge

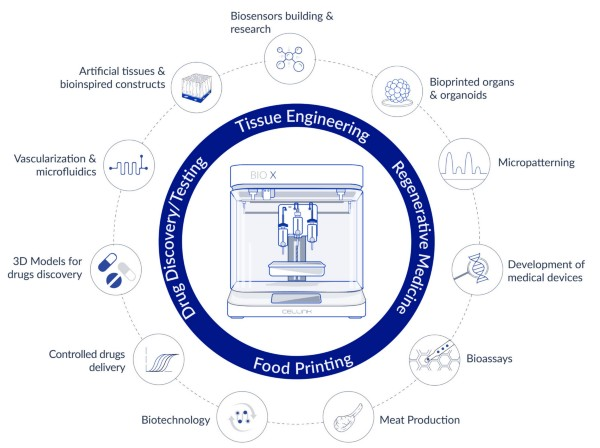

Typically, gelatin, collagen, alginate and fibrin hydrogels are used in 3D bioprinting and tissue engineering because of their extracellular matrix (ECM) properties. However, the search for other natural ECM-like polymers has lagged behind. Chitosan, a natural, biocompatible and biodegradable polymer, has been approved by the FDA and EMA for use in wound dressings, but it is not stable under physiological conditions.

Solution

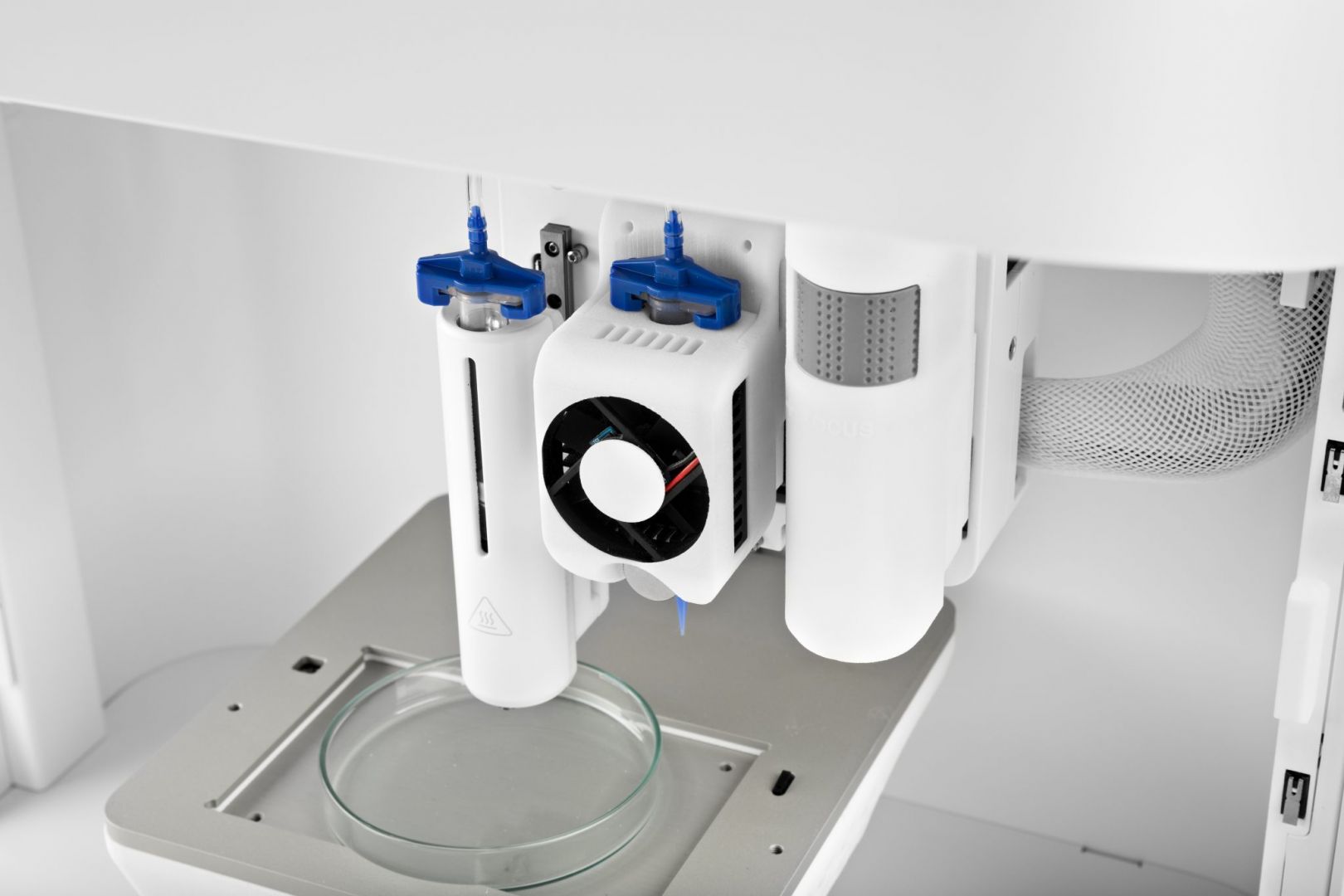

Conti et al. discovered that because of their ionic interactions and rheological properties, 3D bioprinting of chitosan and gamma-PGA structures together at certain concentrations of the biopolymer and crosslinker resulted in more favorable constructs. The CELLINK INKREDIBLE+ bioprinter was used to explore the bioprinting properties of this bioink formulation in order to compare it to other natural ECM material formulations.

Results

The 3D structures generated by the INKREDIBLE+ confirmed that the chitosan-gamma-PGA formulation is biocompatible and stable under shear stresses greater than that of human arteries and veins.

Read more

Preliminary investigation on a new natural based poly(gamma‐glutamic acid)/chitosan bioink. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2020. DOI: 10.1002/jbm.b.34602.